Changing coil prices is one of the tedious realities of running a vending business. It goes like this:

- Print out a giant Excel file of current machine prices and new prices to update.

- Determine a road map of machines that need price changes.

- Hand off to an experienced tech.

- The tech drives around to visit as many machines as they can in one day.

Even if you’ve moved away from using price stickers, you’re still relying on one person to physically key in the new price for each product in each machine. That means time and money.

As other operators can attest, implementing Remote Price Change within Seed® has transformed their processes and increased their revenue.

Switching from reactive to proactive

Inflation happens. Vendors raise their prices. Fuel costs fluctuate.

Which makes price changes across machines a necessity.

“It used to be two price changes per year was the max, and it would take us three or four months to get all our machines updated. Now, we’re getting 10+ price increases from the same supplier just this year. The old way of doing things just doesn’t work anymore,” according to Tim McAra, Senior VP of Refreshment Services at Continental Services.

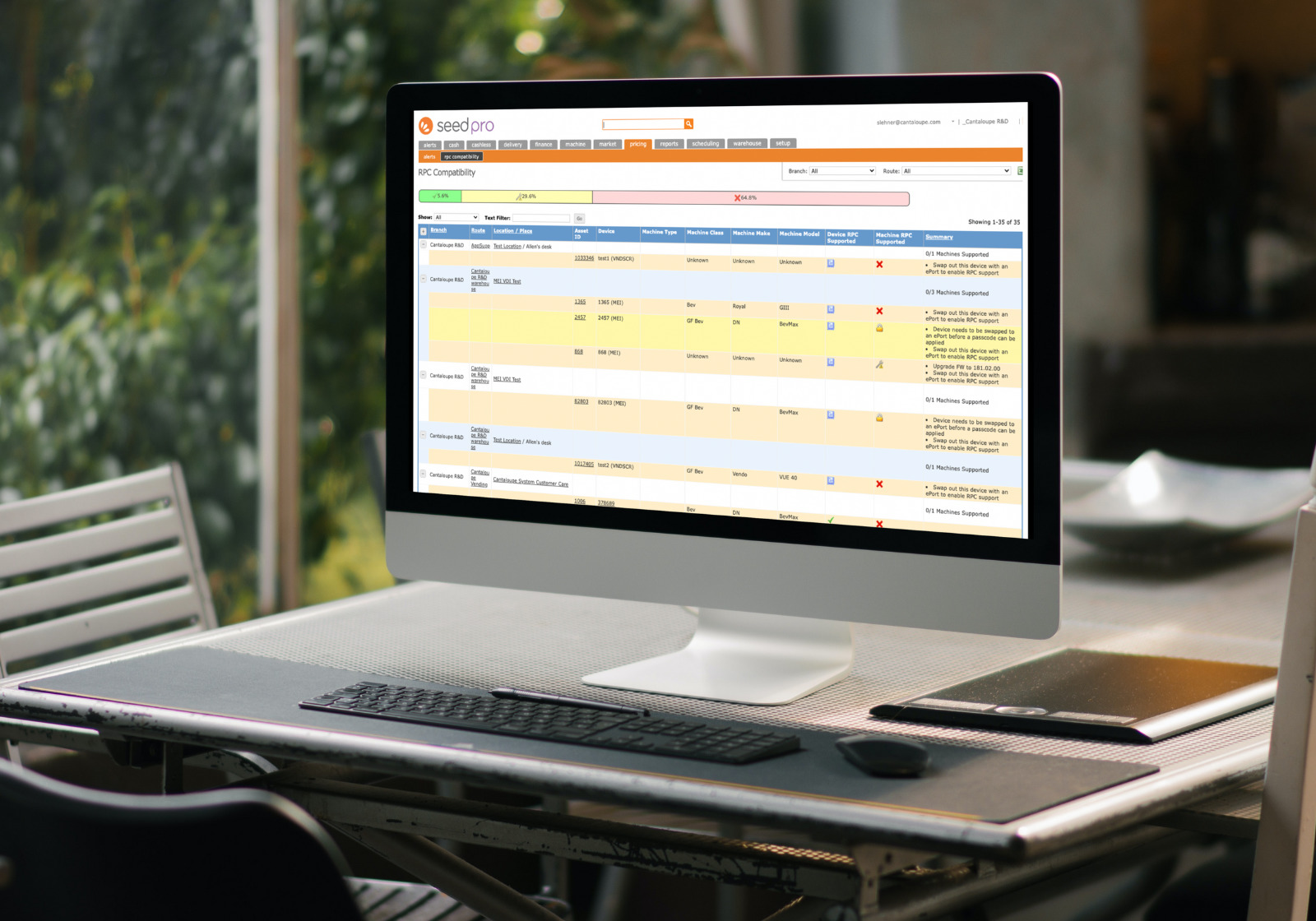

Whether you have a fleet of several hundred or several thousand vending machines to manage, Remote Price Change (RPC) lets you update the coil prices in your vending machines directly within Seed Pro or Seed Cashless+ — from any computer, phone, or tablet. Rather than trying to plan out routes for a tech that include machine servicing and price changing, you can just update coil prices from the office whenever you need or want.

For Joseph Barnett, branch manager with Refresh Sips & Eats in Mississippi, running RPC “saves a lot of man-hour expenses. Instead of sending a tech out there to do a physical change on a machine, it’s an instant, overnight change.

Doing the math

RPC can make a huge impact on the time investment needed to change product prices across machines. So how often are operators changing prices and how long does it take?

Brian Potts, Data Analyst and Systems Administrator at Continental Services, found that “before, a bank of four machines used to take 30 minutes. Now, we can do 100 machines in 30 minutes, without putting any trucks in the field.”

According to Joseph Barnett, his business is regularly running RPC “on 700 – 800 machines weekly.”

But what about the cost savings?

Operators who’ve already adopted RPC are finding that not only is it cheaper to change prices remotely, but they’re seeing increased revenue because they can change prices in near-real time. “If it takes you six months to do a price change, that’s six months of transactions at the lower price — which is revenue that you aren’t seeing,” says Tim McAra. So you have to think: If the cost of a product goes up 25 cents, wouldn’t it be better to change the price in your machines now instead of months in the future?

As an operator, you know how to calculate your business costs against the revenue from your machines. And for a business that runs on tight margins, you can’t afford to rely on these labor-intensive, manual processes anymore.

“At our largest college campus, it would take three weeks to change prices. Now, it takes three days.”

Brian Potts, Data Analyst and Systems Administrator at Continental Services

Evolving the way you do business

One last thing to consider is how RPC can prepare your business for the future. Just take it from Tim McAra: “The inability to react to the marketplace changes is going to cost you a lot more in the long run. This is where everything is going. If you’re not willing to make this investment in Remote Price Change, you may not be able to continue operating.”

Ready to explore all the benefits of Remote Price Change?